What is Thermoplastic?

Thermoplastic road markings are a durable, versatile, and highly visible material commonly used for creating road and surface markings. Comprising a mixture of resins, pigments, and glass beads, thermoplastic markings are heated to high temperatures and then applied to surfaces where they cool and harden quickly. Known for their longevity and safety features, they’re widely used not only on roads but also in various commercial settings such as warehouses, public transport hubs, and the leisure sector like shopping centres and sport clubs. One key player in this industry is us - Thermmark 👋🏻 - we're a manufacturer of preformed thermoplastic marking products designed to ensure precision, durability, and ease of use in high-traffic areas.

1. Introduction to Thermoplastic Road Markings

Thermoplastic road markings provide excellent longevity and visibility, making them a popular choice for creating traffic lanes, pedestrian crossings, parking spaces, and hazard warnings. Beyond roads, these markings are now being increasingly adopted for specialised use in different environments, such as warehouses for safety zoning, public transportation for bus and tram lanes, and even leisure locations where clear and distinct marking improves navigation and safety.

2. Components and Properties

Thermoplastic markings are made from a combination of resins, pigments, glass beads, and additives. The resins give the material its durability, while pigments provide colour visibility. Glass beads are added to enhance reflectivity, making markings highly visible in low-light or nighttime conditions. The thermoplastic nature of the material allows these markings to melt when heated and form a hard, long-lasting bond with the surface once cooled, making them both resilient and adaptable to various conditions.

3. Manufacturing and Production

The production process for thermoplastic materials involves mixing these components at high temperatures. They are extruded into preformed sheets, then cut into shapes, letters, and other designs ready for application. Preformed thermoplastics are gaining popularity because they offer greater precision, easy application, and quick installation, which is particularly beneficial in high-traffic environments like shopping centres and transportation hubs, where closing off roads and pathways for long periods is less than ideal.

4. Application Techniques

There are several methods to apply thermoplastic road markings. For large road surfaces, thermoplastic is heated in specialised equipment and applied as liquid to the surface. However, in more controlled environments, like warehouses or leisure locations, preformed thermoplastic materials like Thermmark are increasingly used. They come in pre-cut shapes and can be easily applied using a blowtorch to adhere them to the surface.

5. Performance and Durability

One of the biggest benefits of thermoplastic markings is their durability. When properly applied, they can last anywhere from 3 to 10 years, depending on the amount of traffic and environmental conditions. In high-traffic environments like bus stops, tram stations, and industrial warehouses, thermoplastic markings can resist wear from heavy machinery, constant foot traffic, and extreme weather conditions better than traditional paint-based markings.

6. Safety and Compliance

Thermoplastic road markings are designed to comply with international standards for visibility, reflectivity, and durability. Their high skid resistance helps prevent accidents on slippery surfaces, particularly in environments like shopping centres or near pedestrian crossings. Preformed thermoplastics also ensure consistent thickness and high-quality application, ensuring compliance with local traffic laws and safety regulations.

7. Cost and Economic Considerations

While thermoplastic materials may have a higher upfront cost than traditional paints, their durability and lower maintenance costs make them a more cost-effective solution in the long run. For warehouses and industrial settings, using preformed thermoplastic materials minimises downtime, as markings can be applied quickly and last for years without frequent touch-ups. This leads to significant savings over time.

8. Technological Innovations

Advances in thermoplastic technology have led to the development of more environmentally friendly materials and increased efficiency in application methods. At Thermmark, we recycle scrap material from the manufacturing process by incorporating it into new thermoplastic material. Some of the latest innovations include reflective technologies that enhance night-time visibility, and anti-slip coatings ideal for areas like sports facilities and shopping centres where traction is critical.

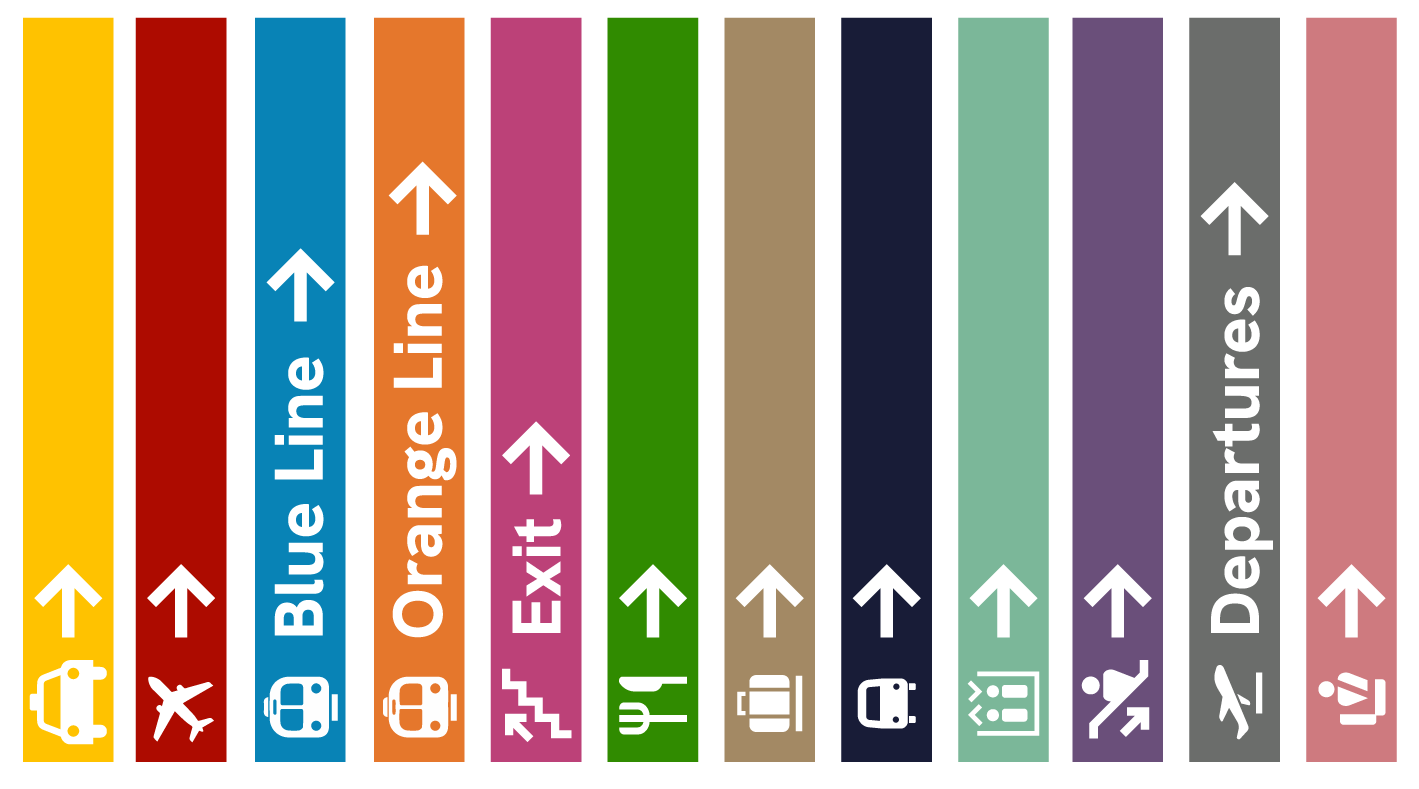

9. Case Studies and Real-World Applications

Warehouses

Thermoplastic markings are increasingly used to outline safety zones, forklift paths, and storage areas, ensuring operational safety and efficiency.

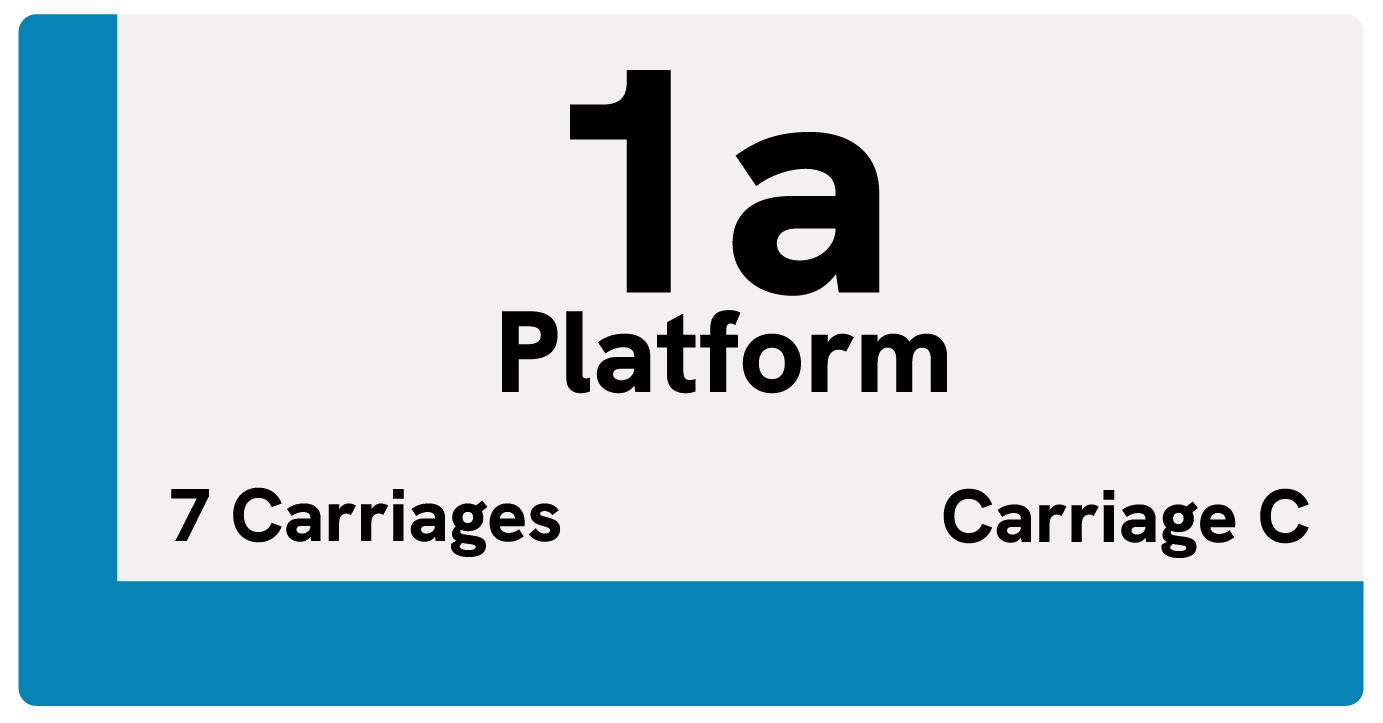

Public Transport

In urban areas, thermoplastic is commonly used to mark bus lanes, pedestrian crossings, and bike lanes. The markings are highly durable and visible, even in heavy traffic.

Leisure

Shopping centres, clubs, and parking facilities are adopting thermoplastic markings to indicate parking spaces, walking paths, and emergency exit routes. Their longevity and easy application ensure these locations remain safe and organised.

10. Environmental and Health Impacts

Thermoplastic markings are often formulated to be more eco-friendly than solvent-based paints. By eliminating the need for frequent reapplications, thermoplastic products like Thermmark reduce the consumption of raw materials and minimise harmful emissions. Additionally, the application process typically produces fewer volatile organic compounds (VOCs), contributing to improved air quality.

11. Training and Education

Proper training in the application of thermoplastic road markings is essential to ensuring long-lasting results. As the properties of the material can differ from manufacturer to manufacturer, Thermmark offers installation guides and training (contact us!) that teach installers how to apply our own material correctly, ensuring compliance with safety regulations and maximising the longevity and appearance of the marking(s).

12. Customer and User Insights

Feedback from customers using thermoplastic markings in warehouses and public spaces is overwhelmingly positive, citing the ease of installation, durability, and improved visibility. Warehouse managers particularly appreciate the reduced need for frequent maintenance, while transport authorities praise the high reflectivity and resistance to wear.

13. Global Market and Trends

The global market for thermoplastic road markings is growing steadily, driven by increased urbanisation, the need for efficient traffic management, and the expansion of warehouse and industrial sectors. Countries across Europe, North America, and Asia-Pacific are adopting thermoplastic solutions for both roads and commercial applications. Market trends also show a growing interest in sustainable and smart marking technologies.

14. Challenges and Solutions

One of the challenges with thermoplastic road markings is the higher upfront cost compared to other materials. However, solutions such as preformed thermoplastic products have emerged to streamline application processes, reduce installation times, and minimise the overall cost in high-traffic environments. Additionally, the ongoing innovation in eco-friendly marking technologies is addressing environmental concerns, further improving the viability of thermoplastic as a future-proof solution.